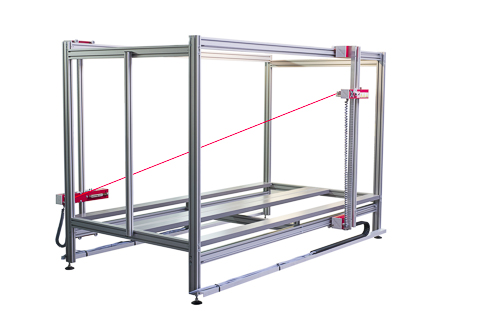

ThermoCut Pro hotwire foamcutter

ThermoCut Pro hotwire foamcutter

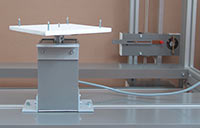

A ThermoCut Pro is a computer-driven cutting machine that can heat to 800 C a strung resistance wire. This heat vaporizes the material nearby, consequently, it cuts the material. Digital storage of cutting parameters of different materials makes possible a high precision cutting.

The ThermoCut Pro foam-cutter enables the cutting of 3D shapes out of extruded or expanded foams (the bulk density of which is less than 60 kg/m3), as e.g.:

• expanded polystyrene foam (EPS)

• extruded polystyrene foam (XPS)

A comprehensive three dimensional shape cutting solution for businesses. Low-cost production from advertising to architecture.

ThermoCut Pro |

60 /P |

60 /PTS |

130 /P |

130 /PTS |

240 /P |

240 /PTS |

300 /PTS |

||||||

| Basic | Mini | Midi | Max | Baby | Mini | Mini | Midi | Max | Mini | Midi | Max | ||

| cutting length (X workspace) [cm] |

130 | 130 | 240 | 300 | 60 | 130 | 130 | 240 | 300 | 130 | 240 | 300 | |

| cutting height (Y workspace) [cm] |

120 | 120 | 60 | 120 | 120 | 120 | 120 | 120 | |||||

| wire length ~ max. foam thickness (V) [cm] |

60 | 130 | 240 | 300 | |||||||||

| wire | Titanium resistance wire (long life, high speed cutting) | ||||||||||||

| wire diameter [mm] | 0.25 | 0.25 | 0.25 | 0.25 | 0.35 | 0.35 | 0.35 | ||||||

| shapeable wire diameter [mm] | - | 0.9 | option* | 0.9 | - | - | - | ||||||

| addressable resolution | 0.01mm | ||||||||||||

| max. shift speed | 700 cm/min. | ||||||||||||

| max. working speed | 280 cm/min. | ||||||||||||

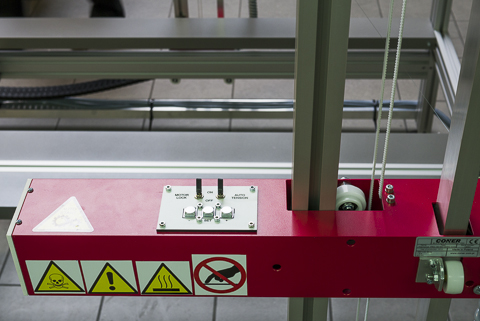

| resistant wire cooling | 2 cooling fans | ||||||||||||

| wire tension | automatic with springs | ||||||||||||

| number of stepping motors | 6 | 6+1 | 6 | 6+1 | 6 | 6+1 | 6+1 | ||||||

| foam cutter construction | aluminium, anodic constructional profile with increased strength | ||||||||||||

| power supply | 230V / 50Hz | ||||||||||||

| power consumption | 650 W |

||||||||||||

| /T | turntable / lathe function | no | yes# | option* | yes# | opt.# | yes# | yes# | |||||

| mountable in vertical or horizontal; for revolving and 3D objects | |||||||||||||

| /S | shapeable wire | no | yes | option* | yes | opt.* | yes | yes | |||||

| special adapter + 2 m formable, shapeable resistance wire | |||||||||||||

| /P | perspective cutting (independent arm motion) |

yes | |||||||||||

| interface | USB port | ||||||||||||

| input format | SoftCut soft ware can cut

drawings from HP-GL (.plt)

or DXF files. 3D objects can be imported from 3D RAW Triangle files. |

||||||||||||

| recommended drawing software |

Vectorgraphical software, like CorelDraw or similar with HPGL data export possibility. AutoCAD. 3D modeling applications, e.g. Rhino 3D software can create RAW Triangle 3D files. |

||||||||||||

| warranty | 1 year full** + 4 years for parts | ||||||||||||

| 60 /P |

60 /PTS |

130 /P |

130 /PTS |

240 /P |

240 /PTS |

300 /PTS |

|||||||

* Optional

turntable, optional shapeable wire can be ordered only for new

machines.

** In Hungary.

Cutting wire and tooth belt aren't covered by warranty.

# machines shipped with 150 kg S150 motor.

SoftCUT Control Software

| Hardware Requirements: |

|

| Basic Functions: |

|

| Additional Software: |

|

| '/T' Turntable - lathe and turntable, possibility of cutting solids of revolution. |   |

| '/S' Shapeable wire -possibility of cutting solids of revolution with forming wire |  |

|

'/P' Perspective cutting - independent arm motion. |

|

| Titanium wire - High resistance titanium coated wire |

AWT Automatic wire tensioner Element tensioning wire is stepper motor co-working with the spring tensioner through the closed-loop feedback system.

|

Optional parts must be ordered together with foamcutter.

- This item is in Your shopping cart.

Email this page

Email this page Printer-friendly version

Printer-friendly version