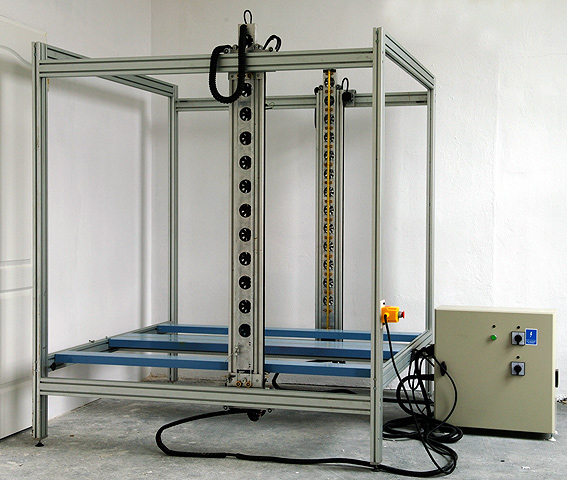

ThermoCut MW15 Multiwire Foamcutter

ThermoCut MW15 Multiwire Foamcutter

- The ThermoCut MW15 can operate with up to 15 cutting wires.

- Ideal for serial production of building decoration mouldings, cornice mouldings, etc.

The lowest wire can cut in the whole of the vertical dimension range. This is why the rotary table can be used with this type. While cutting, the complete vertical column is raised, therefore the machine requires an internal clearance approximately twice its height. i.e. a minimum of 360 cm.

The wires have to be fitted manually, with the help of spanner springs. Clearance between neighbouring filaments may be brought down to a few millimetres. The filaments are held tight by the springs. Operating temperature of the filaments may only be regulated simultaneously meaning that upon changing the number of filaments, the temperature value in the control programme must be readjusted.

Hot wire foam cutters can be primarily used for cutting expanded polystyrene and extruded polystyrene. Expanded polystyrene (EPS) is a cellular structured hard foam, its colour is generally white, and is available in blocks and panels. Extruded polystyrene foam (XPS) is available in panels it is a harder material than the former with a more homogeneous structure.

It is available in various colours depending on the manufacturer. Best known manufacturers and product names: BASF, URSA, JACKODUR.

- Wires can move in the complete vertical dimension range.

- May be used with (optional) rotary table.

| Thermocut Pro 130 MW15 | Thermocut Pro 200 MW15 | |

| Hotwire length | 130 cm | 200 cm |

| Voltage |

3 phase (3 * 230 VAC, 50/60Hz) | |

| Power Supply | 4,5 kW | 6 kW |

| Fuse on the input line |

3 * 20A C | 3 * 25A C |

| Heating | 110 VDC | 150 VDC |

| I/F | USB | |

| Controller | In a Sarel 800*800*300mm case | |

| Controller weight |

100 kg | |

We recommend multiwire machines for cutting expanded polystyrene foam (EPS) blocks. Very high productivity can be achieved.

This type can also cut extruded polystyrene foam (XPS) (with a maximum of 2 wires), but the harder the foam and the larger the total length of operating wires the slower the production process.

Our offer includes (in the base price)

- foam cutter

- controller

- USB interface

- 5 rolls titanium cutting wires

- SOFTCUT sw - in English

- User's Manual - in English

Warranty: 1 year on site + 4 years on parts.